What is oxide shell?

From rolling and steel parts, oxide shell is produced, it is also used as an iron compound in the production of products that need this element.

Regeneration of the oxide shell

There are many methods for recycling or reviving the shells, one of these methods is reviving them with regenerating agents.

These regenerating agents are subjected to regeneration in a fixed bed and at a certain temperature. Regenerative factors include:

Coal coke graphite Production steps, features and applications (please click)

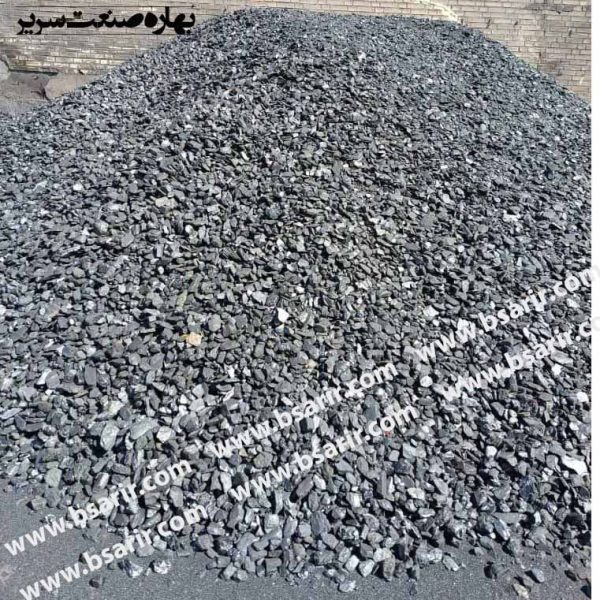

Oxide shell is produced from rolling and steel parts and in the manufacture of products that need this element; is being used. This shell is gray, blue or steel in color and has a very thin coating of hematite. It should be noted that the outer shell of this product is not visible to the eye. The used iron is separated from the surface of the product at high temperature in the process of casting to sheet rolling.

About 2% of rolled steel is removed from production in the form of oxide crust. This shell has about 74% of iron; It has high resistance. It is better to know that this product is sold in bulk and bulk ships of 10,000, 30, and 50,000 tons are used for its transportation. Also, for the internal transfer of this product, machines with jacks and compressors are used to carry it.

Oxidized shell regeneration

There are many methods for revitalizing the oxide shell and recycling it, one of which is the regeneration method. The regeneration of this element is done with factors such as graphite, coke and coal, which are subjected to regeneration at a certain temperature. Recycling this shell causes economic savings, increases productivity and is compatible with the environment. In steel products that are produced by hot rolling method; An oxide crust is found.

In the hot rolling process and at the high temperature of the furnace, there is a layer of feo and wustite between magnetite and steel. 85% of the thickness of the oxide shell is produced from feo, 10-15% from fe304 and about 0.5-2% from fe203. When the part is cooled slowly at a temperature below 1040 F; Most of the feo is converted into fe304 and after it is completely cooled, it has the largest amount of iron oxide metal. This material is used in regeneration conditions in such a way that it does not have a negative effect on the normal process of electric arc furnaces.

Application of oxide shell

Oxide shell is used in many cases, including the following:

This product is used in steelmaking and electric arc furnaces; to save Also, this product is used in the production of ferrosilica, which is used in the casting process to refine the steel structure. Factories that are active in the field of ferrosilicum production; They are one of the main customers of the oxide shell. Among the other uses of this product, we can mention the use in non-ferrous metals and help for melting in factories. Some factories also use this product for granulation and processing. Use in marine pipelines, oil platforms, storage tanks, and optical equipment abrasives are other uses of oxide shell. They also use this product in paper, coloring building materials and magnetic recording tapes.

The price of iron oxide shell

The price of iron oxide shell depends on the size, thickness, quality and type of steel used. Also, the market and geographical area can affect its price. For example, in some markets, the price of iron oxide shell is higher than that of stainless steel.

In general, to know the price of iron oxide shell, you can refer to online sales sites, steel sales representatives or manufacturers and get the necessary information. Also, you can compare the price with several different suppliers to find the best price according to your needs.

Factors affecting the price of iron oxide shell

Various factors affect the price of iron oxide shell, which include:

Type of steel used: The type of steel used to produce iron oxide shell affects its price. For example, stainless steel is usually more expensive than mild steel.

Thickness of the shell: The thickness of the shell also affects its price. Thicker shells have the most strength and resistance, but are also more expensive.

Size and shape of the shell: The size and shape of the shell can also affect its price. Larger shells with complex shapes are usually more expensive.

Market and Geographical Region: The market and geographic region can also affect the price of iron oxide scale. In some markets, its price is higher than in other markets.

Demand and supply: As with other products, demand and supply also affect the price of iron oxide shell. In markets where there is more demand for this product, its price is usually higher.

Production and distribution conditions: Production and distribution conditions can also affect the price of iron oxide shell. For example, production and transportation costs may be higher in some regions, leading to higher iron oxide shell prices.

Production technology: Production technology can also affect the price of iron oxide shell. The use of advanced and modern technologies usually leads to more costs, which leads to an increase in the price of iron oxide shell.

Economic conditions: economic conditions and exchange rates can also affect the price of iron oxide shell. For example, if the exchange rate is high, the cost of importing raw materials for the production of iron oxide shell increases, which leads to an increase in its price.

Production costs: Production costs also affect the price of iron oxide shell. Production costs include manpower costs, machinery rental, maintenance costs and other production costs that can be added to the final cost of iron oxide shell.

نظر مشتریان